Development and design

Our construction tasks are executed using 3D software like Solid Edge and Solidworks.

Laser cutting

Precise material cutting is carried out using high-end TRUMPF laser cutting machines.

| TRUMPF TruLaser 3030 FIBER and TruLaser 3530 lasers | |

|---|---|

| Power output | 4.000 W |

| Workpiece dimensions | 3.000 x 1.500 mm |

| Max. workpiece thickness | steel 20 mm / stainless steel 20 mm / aluminium 20 mm / copper 8 mm / brass 8 mm |

| Accuracy | ± 0,1 mm (based on the workpiece size) |

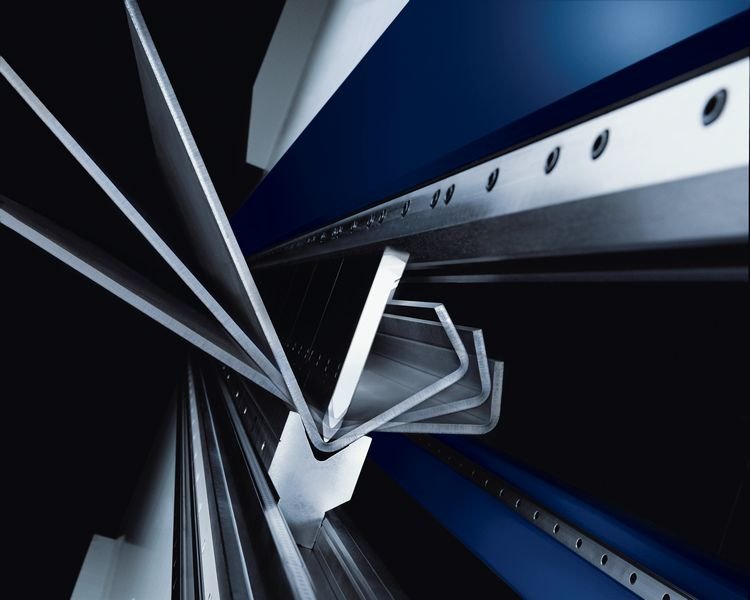

CNC bending

We perform precise bending of sheet metal components with TRUMPF CNC press brakes, equipped with many tools and sensor-based angle control.

| TRUMPF TrumaBend 5085, 5170 and V130 | |

|---|---|

| Press force: | 850-1.700 kN |

| Max bending length: | 3.000 mm |

| Max workpiece thickness: | 12 mm in length approximately 1.000 mm |

| Bending accuracy: | up to 0,5° (depends on material thickness and size) |

| Opening: | 615 mm |

| Extra extension: | 420 mm |

| Width between columns: | 2.690 mm for extension of 420 mm |

Welding

We offer welding using modern MIG/MAG/TIG techniques in protective atmospheres with both active and inert gases.

We weld:

Metalwork and locksmith operations

We provide extensive possibilities for metalwork according to customer drawings and specifications.

CMM measuring

For highly precise 3D measurements and FAI protocols, we use the Mitutoyo Crysta Apex S 710 measuring machine, which provides measurement accuracy in units of microns.

| 3D SMS Mitutoyo Crystal Apex S 710 | |

|---|---|

| Accuracy: | 0,001 mm depending to the measured dimension |

| Range: | 700 x 1.000 x 600 mm |

| Max. workpiece weight: | 1.000 kg |

| Max. workpiece height: | 800 mm |

| Resolution: | 0,1 µm |

Precision example: We can measure a length of 450 mm with an accuracy of 0.001 mm, and the error for this dimension is 3.05 µm = 0.00305 mm.

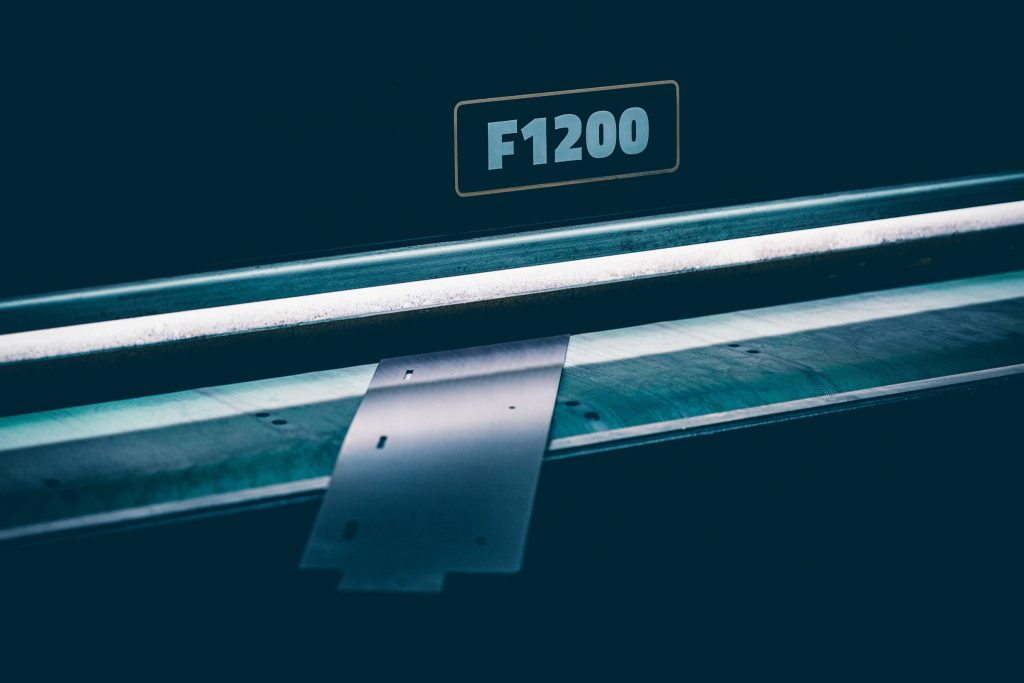

Surface cleaning and deburring

We carry out mechine and manual removal of burrs, splashes and deburring of sharp edges laser parts including surface unification.

| DEBURRING MACHINE Q-FIN 1200 |

|

|---|---|

| Min workpiece dimensions: | 80×80 mm |

| Min workpiece thickness: | 1 mm |

| Max workpiece thickness: | 150 mm |

| Max workpiece width: | 1.200 mm |

| Max workpiece length: | 2.500 mm |

| Materials: | Stainless steel, Aluminium, Steel |

Each type of material is processed using its dedicated set of grinding tools to prevent material contamination and potential corrosion.

| Vibratory tumbler with a dryer | |

|---|---|

| Min workpiece area: | 300×300 mm (flat) |

| Materials: | Stainless steel, Aluminium, Steel |

We use tumbling for deburring,edge rounding, the cutting surface oxide removal and surface smoothing before coating. Parts are tumbled between abrasive media using vibrational motion during vibratory tumbling. Parts made of structural steel are passivated against corrosion and dried in a dryer.

Surface treatment

Surface treatments are used for processing surfaces or applying a layer of a material, primarily to enhance corrosion resistance or improve surface properties (mechanical, chemical, aesthetic, etc.)

Most frequently performed surface treatments:

Material spectral analysis

Mobile spectrometer Belec Compact Port

Aluminum sawing

We process your aluminum profiles with 7 saws. We can produce up to 800 000 parts weekly. With a 5 ton crane and 1000m2 of space, we can enable easy handling, which means we can achieve short throughput times and quick profile changes on the saws.

| Our saws can process the following dimensions: | |

|---|---|

| Max. width: | 500 mm (at approx. 50mm profile height) |

| Max. height: | 180 mm |

KOVO-PLAZMA s.r.o.

IČO: 25550926

DIČ: CZ25550926

b.a. CZK: 372300223/0300

SWIFT: CEKOCZPP

IBAN: CZ5003000000000372300223

b.a. EUR: 195650176/0300

SWIFT: CEKOCZPP

IBAN: CZ1503000000000195650176

Production:

Brněnská 537

66442 Modřice

Česká republika

Billing address:

Běly Pažoutové 30

624 00 Brno

Opening Hours

Order intake:

mo-fr:

07:30 – 11:00

11:30 – 15:00

Order expedition:

mo-fr:

07:30 – 11:30

12:00 – 15:00

tel: +420 531 010 101

e-mail: obchod@kovoplazma.cz